riskassessment – L8, HSG274, BS8580, BG01, BG02, BG04, BG08 and INDG436

Risk Assessment for Water Treatment, Water Hygiene, Cooling Towers, Evaporative Condensers, Process Water Treatment, Boiler Water Treatment and Steam. Risk Assessment for the Approved Code of Practice L8, HSG274 and BS 8580:-1:2019 for Water Hygiene, control of Legionellosis and Legionnaires’ Disease. Risk Assessment for boiler water treatment for steam boilers and steam generators for INDG436, BG01, BG04 and BG08 (hire boilers) Risk Assessment for the prevention of system failure in Industrial, Commercial, Heating, Cooling, and Steam Production systems.

Risk assessment is central to everything we do: If not maintained properly, water systems can quickly slip out of control, becoming contaminated with bacteria or by waterside conditions becoming aggressive to pipework and products. This can in turn lead to proliferation of bacteria, such as Legionella or Pseudomonas or corrosion failure, due to unrestricted ingress of oxygen. Waterborne contamination can additionally spread diseases such as Legionellosis or viruses linked to Pseudomonas.

It is absolutely vital therefore to undertake a suitable and sufficient risk assessment related to the plant and system, in question.

Water Hygiene and Legionellosis Risk Assessments are written with consideration to HSG274 and Steam Boilerhouse Risk Assessments are written in accordance with the requirements of BG04 Boiler Water Treatment-Guidance for Shell Boilers, Coil Boilers, Steam Generators and Hot Water Boilers 2016 and Health and Safety Executive Document INDG436.

We assess risk by testing your plant on-site and providing immediate, colour-coded reports to flag up potential issues.

We can carry out treatment of distributed and process water to all relevant standards, including, but not limited to:

- Health and Safety Executive’s HSG274

- Water Supply Regulations 1999

- BSRIA Application Guide BG50 2013 and BG29 2020

- NHS Technical Memorandum HTM-04

- BS8552 Sampling and monitoring of water from building services closed systems. Code of practice.

- BS2486 Recommendations for treatment of water for steam boilers and water heaters

- BG04 Boiler Water Treatment-Guidance for Shell Boilers, Coil Boilers, Steam Generators and Hot Water Boilers 2016

- BG50 Water treatment for closed heating and cooling systems

- BG29 Pre-commission cleaning of pipework systems

- BS EN 12953 -10 2003 Shell boilers. Requirements for feedwater and boiler water quality

- BS 8580-1:2019 Water Quality risk assessment for control. Code of practice

Cold and Hot Water Systems, Cooling Towers and Evaporative Condensers

To comply with the Health and Safety at Work Act COSHH regulations, HSG274 Legionnaires ‘Disease’ Technical Guidance requires the following boiler measures are required to be put in place for any water system that is ‘deemed to be at risk’:

- Identify and assess risk

- Prepare a scheme for prevention and control – the “Written Control Scheme”

- Keep records of precautions

- Document all measures which are put in place to control risk, using a log-book and/or web based system such as vSteam®.

- Appoint a competent Statutory Duty Holder and Responsible Persons

These measures have to be implemented and reviewed by ‘Qualified and resourceful staff’ who are deemed to be competent. The Code of Practice also require that ‘ongoing dialogue between the supplier and the site’s responsible person is maintained’.

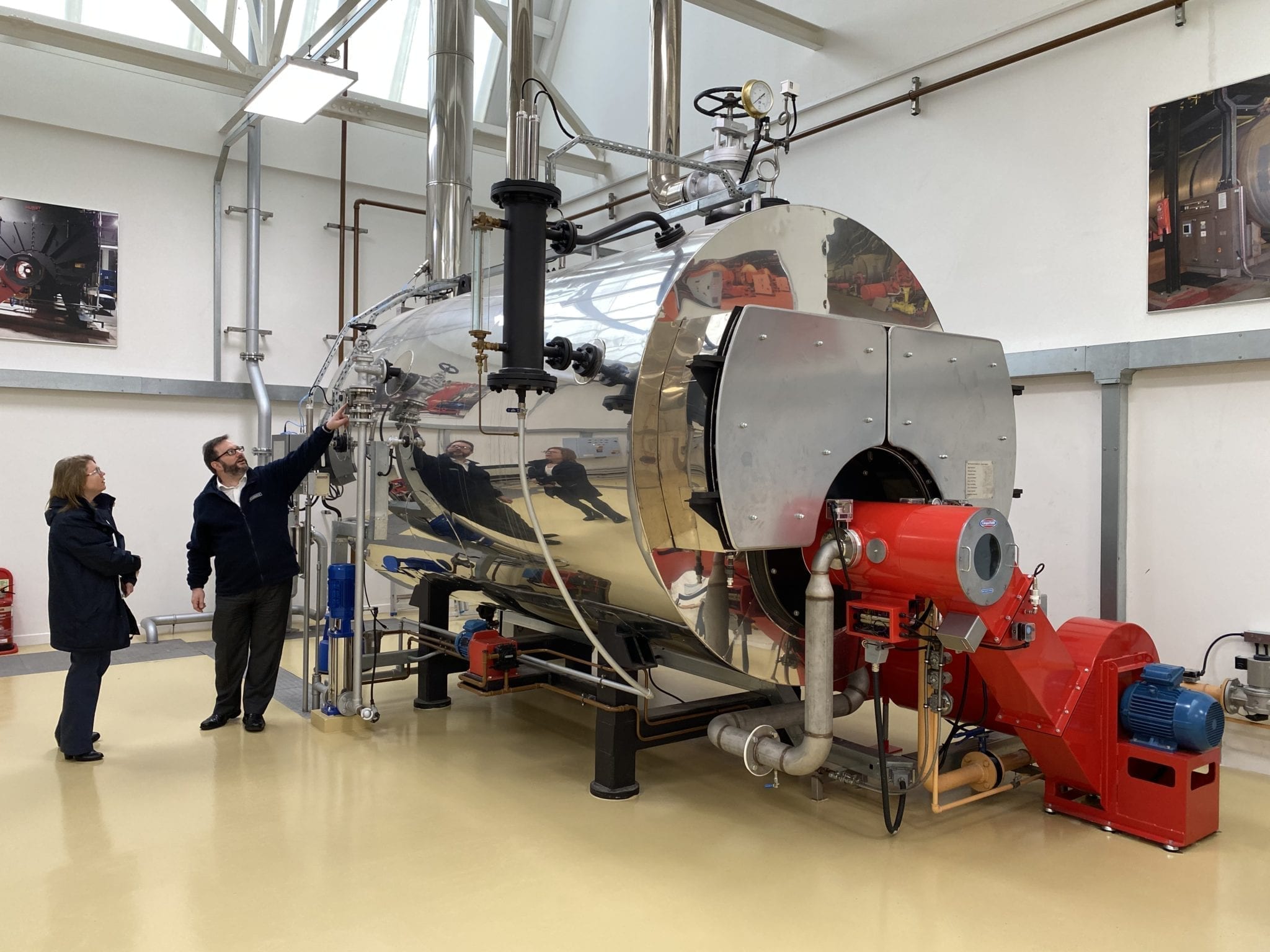

Steam Boilers, Steam Generators and Hot Water Boilers

- To comply with the Health and Safety at Work Act, COSHH regulations, the management of Health and Safety at Work Regulations and BG04 Boiler Water Treatment-Guidance for Shell Boilers, Coil Boilers, Steam Generators and Hot Water Boilers, requires the following measures are required to be put in place for any water system that is ‘deemed to be at risk’, within the scope of the document:

- Identify and assess risk

- Prepare a scheme for prevention and control – the “Written Control Scheme”

- Keep records of precautions

- Document all measures which are put in place to control risk, using a log-book and/or web based system such as vSteam®.

- Appoint a Statutory Duty Holder and Responsible Persons

These measures have to be implemented and reviewed by ‘Qualified and resourceful staff’ who are deemed to be competent. The Code of Practice also requires that ‘ongoing dialogue between the supplier and the site’s responsible person is maintained’.

This legal obligation therefore requires a partnership between engineers, production managers, estates managers, maintenance staff and specialists. We always take a very active role in this partnership, ensuring every area of operation is regularly checked.

All reports are laid out simply, with colour-coded instructions so you and your team can manage your systems with ease.

To discuss risk assessment for any aspect of your water treatment and hygiene in more detail, call us on 0870 460 2980.